FST-RP-LSS2F2H Separation Dehydration Filter Element

Basic Info

Model No.: FST-RP-LSS2F2H Separation Dehydration Filter Element

Product Description

FST-RP-LSS2F2H Separation Dehydration Filter Element:

Production descible:

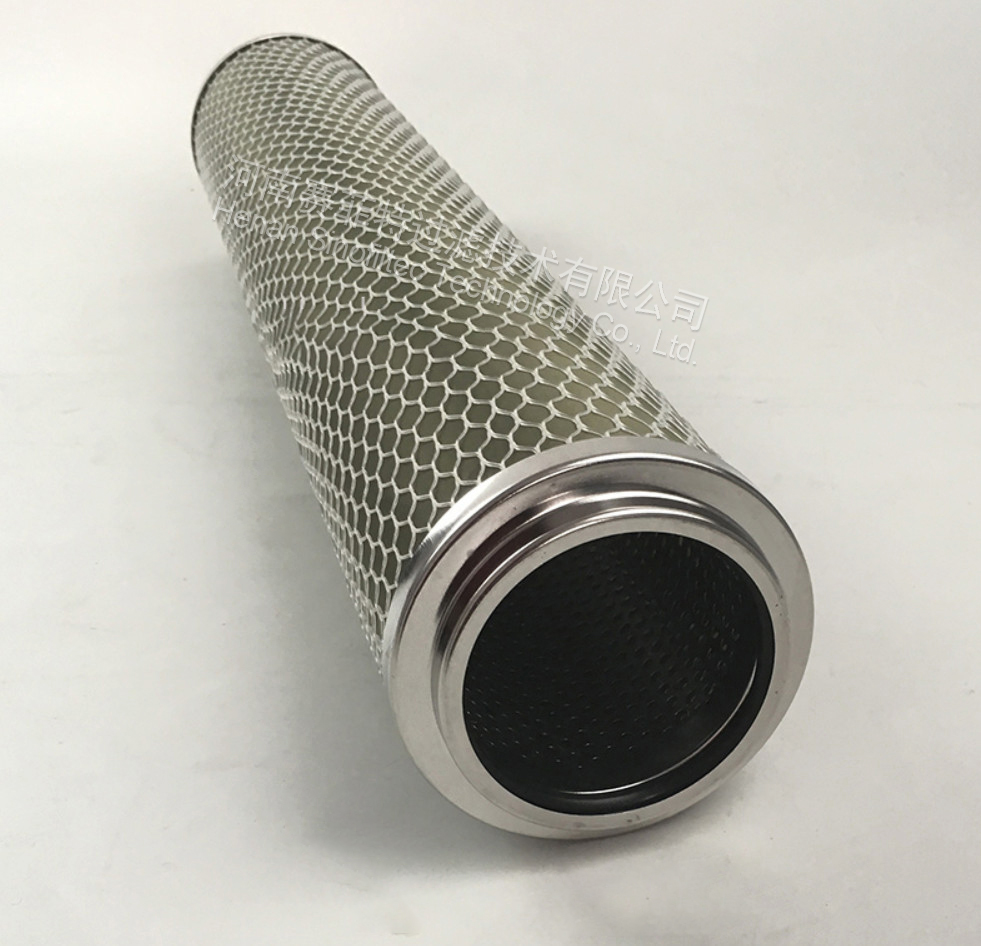

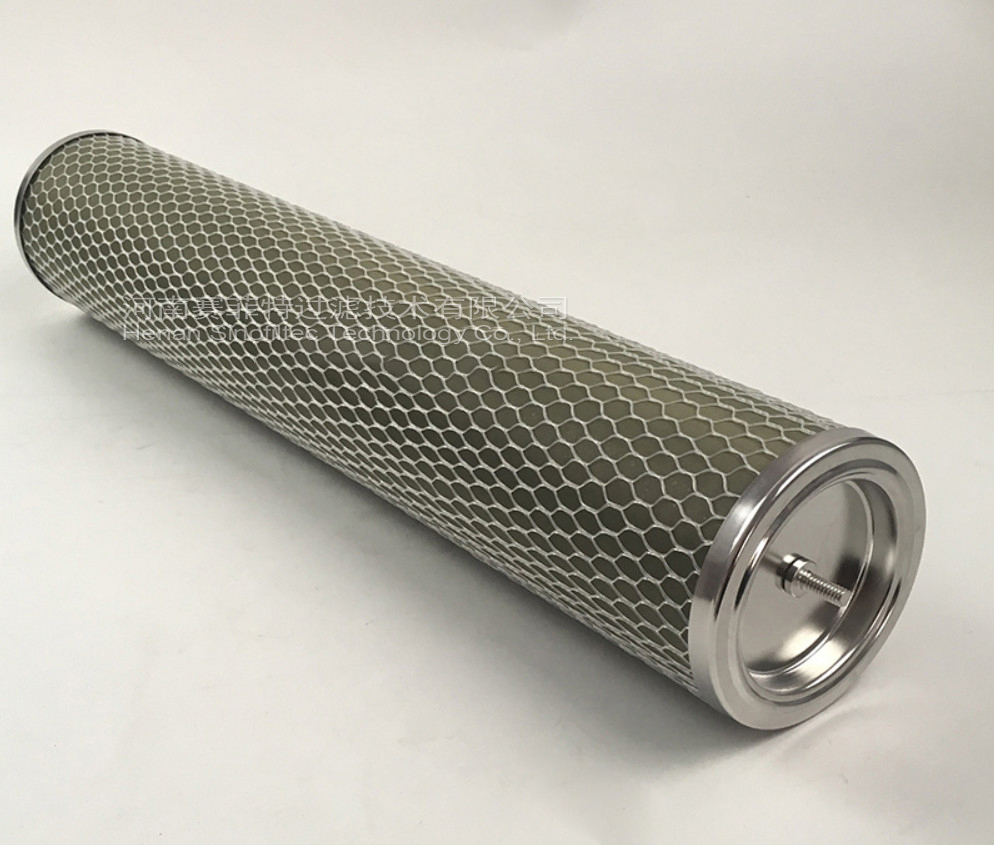

Separation filter element (FST-RP-LSS2F2H ) is a kind of filter element designed for power industry. It is widely used in steam turbine lubrication system and transformer insulation cooling system. Sometimes it needs to be used in conjunction with the coalescence filter. The separation filter is made of a special hydrophilic material. When the oil passes through the separation filter, the water droplets are blocked on the outer surface of the filter. Coalesce until gravity settles into the separator's storage tank. It can effectively remove particles impurity and emulsified water in oil, free water, thus do not damage the quality of crude oil.

Characteristics and advantages:

The filtration effect is better, the flow is high and the dehydration effect is quite stable by using reasonable special material combination. Instead of PALL LSS2F2H filter element, the size is exactly the same, can completely replace the original factory products, achieve the original plant filtration effect. It can be used to remove water and other mechanical impurities in hydraulic system and keep it clean, which can prolong the life of hydraulic system.

Mainly advantages:

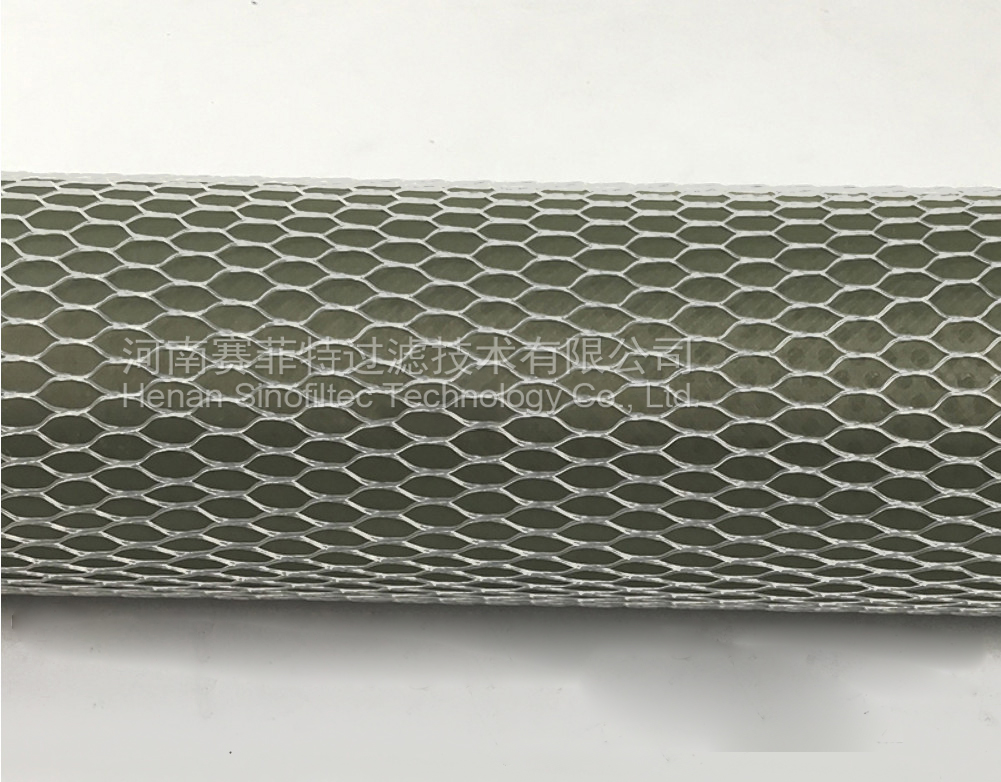

(1) A new filter material is made for the filter element. The multi-layer filtration structure ensures the ability of separation of high contamination and dirty pollution, uniform texture, corrosion resistance and fatigue resistance.

(2) innovating longitudinal joint technology and perfectly joining the end of filter material, especially under different loads, the effective value can prevent suspended particles from entering the filter zone from the dirt area.

(3) the original imported filter media has uniform aperture, low resistance and large dust capacity.

(4) oil-resistant and temperature-resistant cyclopropyl resin adhesive. The seal is firm.

(5) thickened steel plate skeleton. Strong pressure drop resistance.

(6) to leave the factory after passing the inspection. The quality is reliable.

Technical Data:

| Type of the filter element | High-efficiency filter cylinder |

| Filter medium | Teflon hydrophobic material |

| Filtration accuracy of glass fiber filter material | 50~100 microns available |

| Internal support and end cover material | Metallized tin / reinforced nylon / stainless steel |

| Working temperature | -10℃~120℃ |

| Working pressure | 5bar~10bar |

Mainly advantages:

(1) A new filter material is made for the filter element. The multi-layer filtration structure ensures the ability of separation of high contamination and dirty pollution, uniform texture, corrosion resistance and fatigue resistance.

(2) innovating longitudinal joint technology and perfectly joining the end of filter material, especially under different loads, the effective value can prevent suspended particles from entering the filter zone from the dirt area.

(3) the original imported filter media has uniform aperture, low resistance and large dust capacity.

(4) oil-resistant and temperature-resistant cyclopropyl resin adhesive. The seal is firm.

(5) thickened steel plate skeleton. Strong pressure drop resistance.

(6) to leave the factory after passing the inspection. The quality is reliable.

Applications:

1.Thermal power and nuclear power industry: gas turbine, boiler lubrication system, speed control system, bypass control system oil purification, feed water pump, fan and dust removal system purification.

2.Metallurgical industry: for rolling mill, continuous casting machine hydraulic system filtration and various lubricating equipment filtration.

3. Petrochemical industry: oil refining, separation and recovery of products and intermediate products in chemical production, purification of liquid, magnetic tape, optical disc and photographic film in manufacture, filtration of oil well water and natural gas.

4.Processing equipment: paper machinery, mining machinery, injection molding machine and large precision machinery lubrication system and compressed air purification, tobacco processing equipment and spraying equipment dust recovery and filtration.

FST-RP-LSS2F2H filter element instead of PALL hydraulic oil filter element execution standard:

ISO2491 filter-rupture resistance experiment:

The test of resistance to rupture of filter element belongs to the strength test of the filter element itself. The filter element is generally subjected to external force by the pressure difference limit after carrying the dirt in the filter shell. The inner skeleton is the main support of the filter layer under the limit pressure difference of the filter element, and the collapse of the skeleton will lead to the collapse of the filter layer.

ISO2492 filter element structural integrity experiment:

The significance of the requirement of the integrity of the filter element structure, the filter material is very good, the filter material is broken or made incomplete in the process of making the filter element, the incomplete phenomenon mainly manifests in: the filter material is damaged, the end cover is not glued strictly, the filter material butt joint is not strict and solid. It will greatly affect the original filtering accuracy.

ISO2493 filter element the compatibility betwee material and liquid experiment:

The compatibility test between filter element and working fluid is mainly a validation test of the properties of raw materials used in the process of making filter elements, such as compatibility with petroleum, water diol, water-oil emulsion and liquid with high water content. PTFE seals are standard configurations and can be used in conjunction with industrial phosphate, diesters and specific synthetic materials.

ISO3726 filter element experimental method of the end load:

The end load test of the filter element mainly tests the ability of bearing the axial mounting force, the strength, the axial load, the flattening strength and so on.

ISO3724 filter element the determination of fatigue characteristics:

The test of the fatigue characteristics of the filter element is the test of the life of the filter element. The filter element works in the hydraulic system, withstanding the reciprocating and alternating fluid flow of the system and the pressure impact of the working flow. Under this impact, if the filter element has accumulated pollutants and established a greater pressure difference, then the pressure of the filter layer withstanding the fluid flow will be greater.

ISO3968 filter element determination of flow characteristics and the pressure difference:

The pressure drop flow characteristic is usually an assessment of the filter, but in fact, it mainly evaluates the flow rate and resistance of the filter core. Of course, in the design of filter assembly, there are flow and

bypass problems in the channel design of the shell. But after all, it is not the main problem, the main problem is the filter, so the standard mainly checks the filter, not the filter.

Contact us if you need more details on LSS2F2H Separation Dehydration Filter Element. We are ready to answer your questions on packaging, logistics, certification or any other aspects about PALL Separation Dehydration Filter Element、PALL LSS2F2H Dehydration Filter Element. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Customized Filter Elements > Coalescence &separation Filter Elements